Air Treatment

The Pneurop Committee 14 (PN 14) leads the way for air treatment manufacturers in the compressor field in the expanding European Union.

From the original simplistic concept in 1959 to “Identify a contaminant classification system for compressed air”. The approach now is to broaden the knowledge of the user to the vast array of technology and standards available. This to be achieved through the re-statement of the goal:

To devise, develop and promote air treatment technology and standards in the compressed air field.

The manufacturer members come from the trade associations of the member countries of PNEUROP to exchange views and opinions that are distilled and result in the production of publications which then in time to become ISO standards.

PNEUROP in close cooperation with its US partner organisation CAGI are working towards the provision of global acceptance of common standards through their joint support of the ISO TC118 SC4 activities.

The users of the standards can be:

- Manufacturers, who can make use of the standards when they are designing and rating their products.

- Customers/end users, who can use the standards to specify their requirements concerning purity and when evaluating different quotations.

- Laboratories, who will be involved when verifying if compliance has been reached between the requirements and results.

- Legislation, to use the standards in order to prove compliance with legal aspects.

Industry

Solutions now lead the way in the compressed air market. The manufacturer seeks to satisfy the challenges of the customer with novel and ever more complex equipment. As a result of this there has to be a real partnership between the manufacturer and the customer. The need to innovate is seen as the way to ensure a high level of compressed air efficiency and reliability.

More widespread and demanding applications of compressed air have governed the requirements concerning compressed air quality to become more critical. Compressed air is applied in many sectors of technology, for example in the pharmaceutical industry, when manufacturing vaccines or antibiotics, in the food and beverage industry, in hospitals and also manufacturing in the electronic industry. All these compressed air users depend on purified compressed air.

From providing simplistic filters as a common solution in the early days of industrial, construction and mining applications to today’s array of filtration, drying and separation techniques have been developed to provide the solutions to the demanding applications required by the customer.

So instead of a simple bed of ‘salt’ to act as a means of drying air there are refrigerant systems, desiccant systems and membranes to remove water and then there are devices which separate oil/water mixtures before disposals and sophisticated devices for discharging the water. Filtration systems which are described as surface and depth filters as well as absolute filters are offered for the many applications needing a solution.

It is also now possible to generate gases such as nitrogen directly from a compressed air supply rather than bring it in as a bottled product.

Innovation helps to move the boundaries of technology forward and it is ever the case in compressed air treatment. With all this innovation the customer needs a confidence that the performance of the product lives up to expectation which brings the discussion back to standards.

Legislation

The description of the make up of Europe and the formation of the EU outlined in the compressor section illustrate very well the reason for the costs incurred by manufacturers in the air treatment world. Where their products inevitably contained some sort of pressure vessel the individual certification costs made the movement of their products an expensive activity. So it was a welcome step forward when in 1994 and then in 2002 at least 2 directives helped to open up the market amongst EU member countries by a single certification system.

Primary legislation which air treatment manufacturers have to comply with:

- Simple Pressure Vessels Directive (SPVD)

- Pressure Equipment Directive (PED)

- Low Voltage Directive (LVD)

- Electromagnetic Compatibility Directive (EMCD)

Other legislation for special uses and applications:

Standardisation

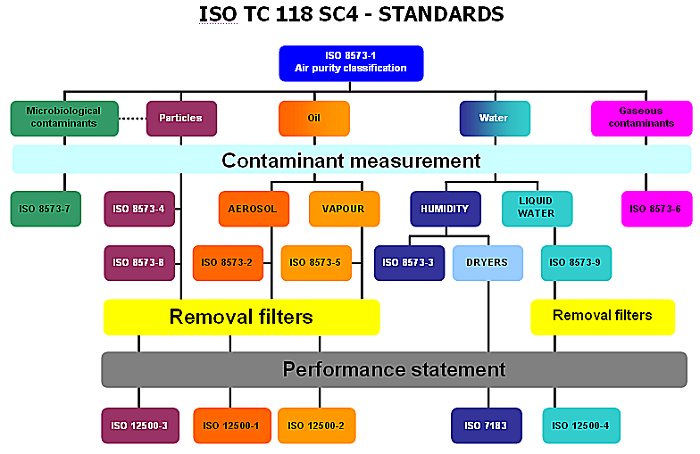

The PNEUROP Air Treatment sector was instrumental in the formation of sub-committee, SC4 “Purity of compressed air”, in the International Standards committee ISO TC118 to progress many of its work items into ISO standards.

The main focus is to improve and extend the standards in the air treatment field. The next step is clear which is to encourage the user to provide experiences of the use of those standards. Feedback through this website on the standards will provide the all important guide in its future work in the revision phases of those standards.

The introduction of filter performance standards in ISO TC118 by the United States organisation CAGI brings a change in emphasise for the PNEUROP Air Treatment sector. There will be a need to evaluate how these standards will affect the technical specification of those filter mechanisms addressed in the ISO 12500 series.

Many users are unaware of the improvements in equipment and the standards on air treatment and as such it is an important issue to communicate the development of both aspects to the user.

Those standards currently available or being developed are show in the diagram below.